3D printing, whilst not new, has been a fairly elusive piece of technology for everyday people. From quirky toys to furniture and even food, 3D printing technology is something that we usually only see as a form of artistic or experimental expression. However, this technological innovation is being explored in other fields as well, including real estate. How? In the form of 3D printed buildings!

With the advent of new technology, construction 3D printing is changing the view and approach to the construction of low-rise buildings and provides new opportunities to implement custom architectural solutions. Imagine homes being built in a day, which are not only sturdy but also cheap and eco-friendly. Well, there’s no need to imagine any more.

Apis Cor, a San Francisco-based company, has successfully 3D-printed a home in a day, and claims it all cost less than US$15,000 (approximately RM66,750).

The completed 3D-printed house (Photo by Apis Cor)

The distinctive-looking home was put together using the latest 3D-printing technology at one of their facilities in Stupino, near Moscow in Russia.

Using a concrete mixture, the company worked with Russian developer PIK Group to produce a 38-square-metre building with a kitchen, bathroom, living room and self-bearing walls. According to the company’s website, the “pure machine time of printing amounted to 24 hours”, with set-up time of around half an hour.

Interior of the house (Photo from Apis Cor)

Other 3D-printed houses have popped up before, most notably in China, but these generally require some individual components to be printed separately – or constructed elsewhere – then assembled together at the final location.

For this latest project, there were some challenges with the weather – in the dead of winter, the temperature was much colder than the minimum 5°C the concrete mixture needed, so a tent was erected around the site to keep the printer warm enough to print.

The 3D printing in action (Photo from Apis Cor)

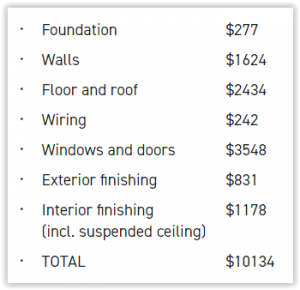

Apis Cor’s distinctive home is expected to last about 175 years – not bad for a day’s work and a budget of US$10,134. This cost includes all the works that were done to make a complete house: work and materials for the construction of foundation, roof, exterior and interior finishing works, installation of heat insulation of walls, windows, floors and ceilings.

Cost of constructing the 3D-printed house (Screenshot from Apis Cor website)

The follow-up work, which include installation of windows, furnishings and an exterior paint job, were added after printing had finished, but if it’s a feat that can be replicated then prefab building could one day be a lot easier.

Giving the house a bright yellow coat of paint (Photo from Apis Cor)

Check out the video of the house-printing process below!

Wouldn’t it be awesome if we could have these 3D-printed homes in Malaysia? Affordable and cozy, could help solve the problem of “severely unaffordable” housing and increase home ownership.

(Sourced from Domain and Apis Cor)

Sign up with Estate123.com to list your properties for FREE today, and follow our Facebook page for more interesting property news and updates!

![SplashMania Water Theme Park @ Gamuda Cove, Banting [Video & Review]](https://insight.estate123.com/wp-content/uploads/2023/04/SplashMania-youtube-thumbnail-440x264.png)